ה Schweisstechnologie הוא טכנולוגיה חדשנית ומודרנית שמשפרת את איכות השweis. shweiss הוא התהליך שבו אנו משתמשים כדי לחבר חומרים יחד, כמו פלדה ואלומיניום.方方面 זה הוא במיוחד חשוב ב-sektoren רבים, כולל בניין ו-fertigung. shweiss נעשה בדרך כלל ידנית, שזה יכול לקחת זמן רב והיישג גדול. אבל עכשיו עם תכנת shweiss הרובוטית של MINYUE, גם הרובוטים יכולים לסייע בשweiß!

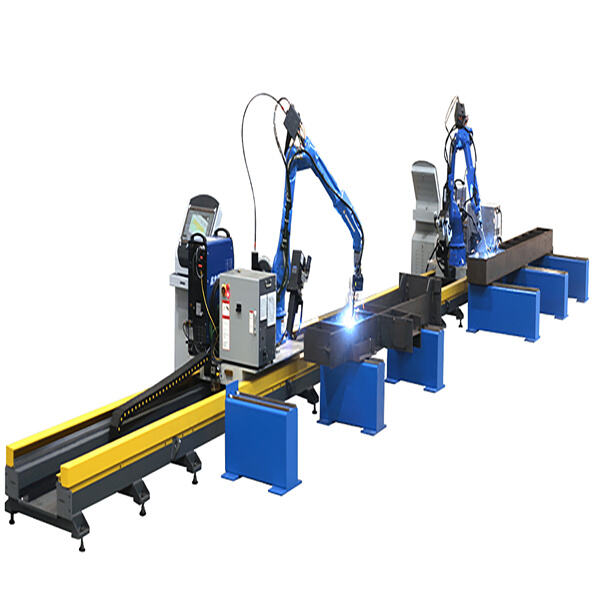

הSHAMAYIM של התעשייה העולמית (MINYUE) מהפיכה את הדרך בה אנו מבצעים חיבור באמצעות חיבורים רובוטיים. זה לא רק ממהר את תהליך החיבור, אלא גם גורם לו להיות מדוייק יותר. עבור פתרונות הובלה מתכת רבים, במקום להסתמך על עובדים לביצוע כל עבודת החיבור, רובוטים יכולים לסיים את המשימה לא רק מהר יותר, אלא גם עם דיוק גדול יותר. זה מאפשר לחברות להשלים את המיזמים שלהם בזמן קצר, מה שמציל אותן זמן וכסף. ככל שהמיזמים מסתיימים מהר יותר, כך החברה יכולה לקחת על עצמה יותר עבודה, מה שגורם לחברות להצליח יותר.

ה Schweissroboter שומרים על זמן של חברות על ידי איפוס להם לעבוד בצורה יותר יעיל. רובוטים יכולים לעבוד ללא הפסקה, יום ולילה, ולא להרגיש עייפות, משהו בלתי אפשרי עבור בני אדם. הם יכולים לחזור על אותן משימות שוב ושוב ללא שגיאות. זמנים מהירים יותר לייצור ושגיאות פחותות אומרות שהחברות יכולות לייצר יותר מוצרים בזמן קצר יותר. פחות שגיאות אומרות שאינן מפסידות כסף ומשאבים על תיקון שגיאות.

יש הרבה סיבות קולות לחברות להשקיע בטכנולוגיה של Schweissroboter. קודם כל, זה יכול לחסוך לחברות כמות עצומה של כסף. הן יכולות לחסוך כסף על עלויות עבודה על ידי ביצוע רובוטים במקום לשכור מספר גדול של עובדים. בנוסף, הם מסוגלים לפעול 24/7, מאפשר לcompaniesto להגדיל את פעילותם ללא ההוצאות של שכר עובדי Schweisser נוספים. לحام נקודה רובוטי היא מועילה ביותר עבור חברות שמחפשות להתפתח. בנוסף, רובוטים יכולים לקחת על עצמם עבודות שסיבוכיות מדי או מסוכנות עבור עובדים אנושיים, מה שמאפשר לעובדים להיות בטוחים יותר ומפחית תאונות עבודה.

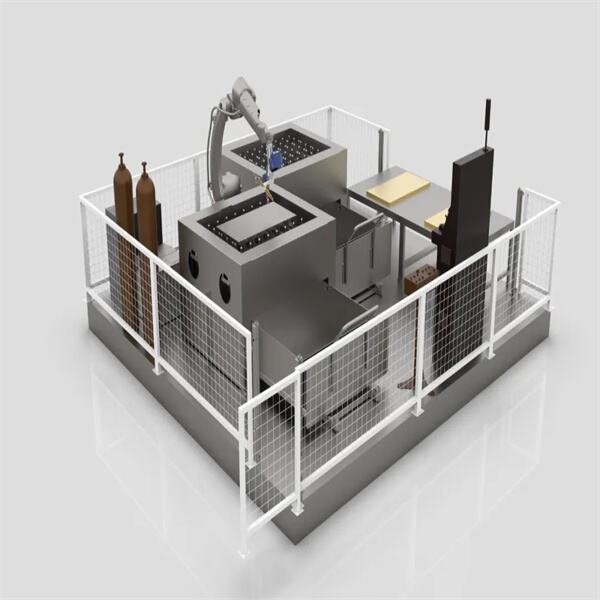

פתרונות פתרונות ההלחצה הרובוטיים של MINYUE מאפשרים ייצור לפעול בצורה חלקה בהרבה. אלו תא הדבקה רובוטית , למשל, יכולים לעזור לחברות להזיז חומרים למקום ולהחזיק אותם במקומם בצורה מאובטחת, משמידים משימות חוזרות. זה מפקר את הצורך בעובדים להשלים את המשימות הללו ידנית, מה שמעודד אותם להתמקד בעבודה מורכבת יותר.ßerdem, רובוטים יכולים לעבוד על מספר פרויקטים בו זמנית. זה מאפשר לעסקים להשלים הרבה פרויקטים בו זמנית ובזמן קצר יותר. רובוטים גם מאפשרים תהליך עיצובoefficient יותר, מה שמפחית את הפסדי החומר שנוצרים משימוש בחומרים לא הכרחיים (מה שטוב עבור כדור הארץ ולרווחיות העסק).

אחת המטרות הגדולות של חיבוב רובוטי היא שהיא מגדילה באופן דרמטי את איכות המוצר הסופי. בניגוד לכך, רובוטים יכולים לחבוב בצורה יותר מדוייקת מאשר עובדים אנושיים, כך שהחיבורים שהם יוצרים יהיו חזקים יותר ועמידים יותר. זה קריטי, מכיוון שחיבורים עמידים מסייעים למוצרים להימשך זמן רב יותר ולהיות יעילים יותר. גם רובוטים לحام למכר יכולים לעשות את אותה משימה בצורה זהה בכל פעם, ובכך החיבושים יהיו באיכות אחידה כל דרך תהליך הייצור. זו הסוג של עקביות שמייצרת אמון עם לקוחות שמתבססים על מוצרים באיכות גבוהה.

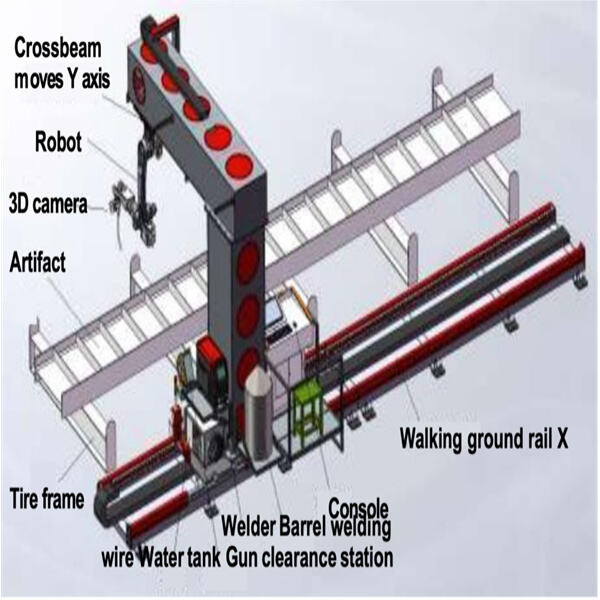

הצג רובוט חיבור חזק עם טעינה מפנימית, טעינת צד, טעינת הפוך, התקנה על גשר, תכנון מסלול חכם עבור מספר רובוטים, מספר צירים חיצוניים ומערכת שיתוף עבודה של מיקום. השיג סימולציה של תנועת רובוט, זיהוי התנגשות, הימנעות מסינגולריות וזיהוי הגבלת ציר.

השימוש בפונקציית איתור והעקבות, סריקת קו הלחימה, אימות מיקום ומידע של קו הלחימה, תיקון המיקום בין הדגם הדיגיטלי התלת מימדי לבין החלק האמיתי, ופתרון בעיית לחימה מוטה עקב טעות בחומרי הגלם ומשתנה תרמי.

חברת בייג'ינג מיניואו טכנולוגיה קוב., ליטד., כחברת טכנולוגיה מתקדמת מובילה בעולם בתחום יישומי רובוטיקה תעשייתית חכמים ללא לימוד. אנו מומחים בייצור חכם ומלאי גמישות באמצעות מערכות החוכמה העצמיות שלנו: RobotSmart - מערכת קבלת החלטות חכמה, SmartVision - מערכת חזות דו-עינית של אור מבני, ו-SmartEye - מערכת עקוב אחר דבק לייזר. מספקים פתרונות חידושים של חיבור וחיתוך רובוטי חכם דור חדש.

מהיר, מדוייק,完全没有 תכנות, יעיל מאוד ובדיוק גבוה. זה פותר את תהליך הלימוד המורכב של הרובוטים המסורתיים ומציל את זמן העצירה של תהליך הלימוד.