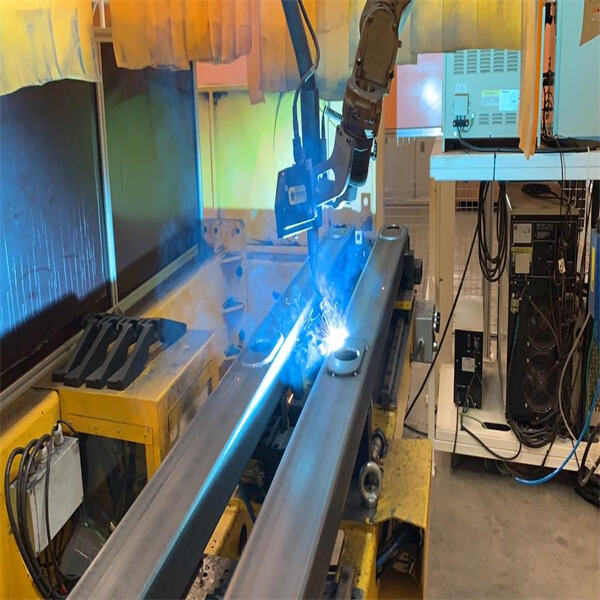

Robotic welding systems are helping to revolutionize assembly. They use robots to join metal pieces together via heat. MINYUE robotic arm welding machine help to make engineering of items, be it cars, buildings, etc. easier and safer. Join us as we delve into the-world-changing technology of robotic welding systems.

Robotic welding systems are a kind of super helper in the field of welding. They can calculate quickly and accurately, and they do not tire like humans do. This means that they can work for a long time without going wrong. Because it makes work easier, and the quality of what is made better, this is transforming the industry.

Robotic welding models allow organizations to produce more products in a shorter time. These systems are able to work with various materials types and produce strong, accurate welds. Fewer mistakes and less work, in other words. Robotic welding systems also improve the speed and reliability of welding systems.

It is very important to be safe at work. Robotic welding systems allow workers to be away from hot metal and smoke. MINYUE automated robotic welding decrease the risk of accidents and injuries that can occur while welding in the standard manner. Implementing safety practices not only helps make the company a better place now, but shows a commitment to doing so in the future.

It may seem expensive at first, but by investing in robotic welding systems, companies can save money in the long run. Human workers need rest but these systems can continue running day and night without any regressive interruptions. That means companies can produce more in less time. Moreover, MINYUE robotic welding automation reduce the waste and cost of rectifying errors. All in all, robotic welding systems are a cost-effective option for businesses that want to enhance their manufacturing process.

Robotic welding systems have an incredible amount of flexibility. MINYUE different types of sensors in robotics can be trained to be efficient in series on various sizes of parts and metal shapes. This flexibility allows companies to apply robotic welding systems in various types of projects. Regardless of whether it is welding small parts for vehicles or joining large beams for structures, robotic welding systems are able to complete various jobs with great ease.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.