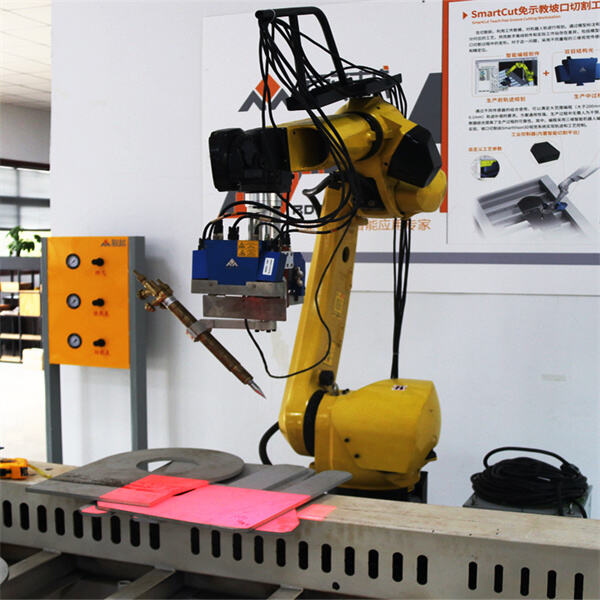

প্রযুক্তি সম্পন্ন হতে থাকছে এবং একটি মজাদার উন্নয়ন হলো রোবোটিক লেজার কাটিং। এটি একটি বিশেষ প্রযুক্তি যা উচ্চতর সঠিকতার সাথে এবং আগের তুলনায় অনেক দ্রুত উপকরণ কাটতে সক্ষম। MINYUE রোবোটিক ওয়েল্ডিং সেল , তারা নিকটতম পণ্য সঠিকভাবে তৈরি করতে পারে। এটি রোবটদের অতিরিক্ত সার্জিকাল ক্ষমতা দেয়, যেটি মিলিমিটার পর্যন্ত। মিলিমিটার একটি ছোট একক, প্রায় একটি পেনসিল লিডের বেধের সমান। এই সঠিকতা অত্যন্ত গুরুত্বপূর্ণ, কারণ এটি নিশ্চিত করে যে অংশগুলি পণ্যের মধ্যে যুক্ত হলে পূর্ণতা সাথে মিলে যায়।

MINYUE রোবটিক প্লাজমা কাটিং ফ্যাক্টরিগুলিকে পরিবর্তন করছে। রোবটের আগে, শ্রমিকদের পণ্য তৈরি করতে হাতে-করে কাজ করতে হত। এটি সত্যিই অত্যন্ত সময়সাপেক্ষ এবং শ্রমসাপেক্ষ প্রক্রিয়া। এর মানে ছিল শ্রমিকদের খুব সাবধান থাকতে হবে, কারণ ভুল খুবই ব্যয়বহুল এবং সময়সাপেক্ষ হতে পারে। কিছু ভুলভাবে কাটলে তা অপরিদর্শিত করতে এবং অপরিদর্শিত হওয়ার কারণে প্রক্রিয়াটি পুনরায় শুরু করতে হবে। আগে এটি সময় লাগত, এখন রোবটিক লেজার কাটিংয়ের মাধ্যমে উৎপাদন সহজ এবং দ্রুত। লেজার কাটার ঘন্টার পর ঘন্টা ব্যবহারের পরেও থাকে এবং তারা খুবই সঠিক কাট করতে সক্ষম। কম্পিউটার যন্ত্রগুলি নিয়ন্ত্রণ করে, তাই তারা মানুষের তুলনায় কম ভুল করে।

রোবোটিক লেজার কাটিং অত্যন্ত পরিবর্তনশীল। এর ফলে এটি বিভিন্ন ধরনের উপকরণ, যেমন ধাতু, প্লাস্টিক এবং যেন কাঠ সহ ছেদ করতে ব্যবহৃত হতে পারে। এই বহুমুখী বৈশিষ্ট্য এটিকে বিভিন্ন জারি দারদের জন্য একটি উপযোগী যন্ত্র করে তোলে। রোবটগুলি প্রোগ্রামযোগ্য, অর্থাৎ তাদেরকে খুবই নির্দিষ্ট কাট করার জন্য নির্দেশ দেওয়া যায়। কারণ MINYUE বিস্তারিত এবং শিল্পীদের ডিজাইনের উপর নির্ভর করে, যদি কোনো কোম্পানি কিছু আলাদা আকৃতি বা প্যাটার্ন তৈরি করতে চায়, তবে রোবটগুলি সেই অনুযায়ী সামঞ্জস্যপূর্ণ করা যায়।

তবে, লেজার কাটিং রোবটের মতো নতুন প্রযুক্তি সventional উৎপাদন পদ্ধতির তুলনায় অনেক সুবিধা আনে। প্রথমতঃ, রোবট মানুষের উপর নির্ভরশীল নয় তাদের কাজ করতে গেলে, যার ফলে কম ভুল হয়। এটি শ্রমিকদের জন্যও খরচ কমায়। যদি একটি কারখানা কম কর্মচারী ব্যবহার করে চালানো যায়, তবে তা বেতন এবং প্রশিক্ষণের উপর অর্থ বাঁচাতে পারে। এছাড়াও, রোবট মানুষের তুলনায় দ্রুত কাজ করতে পারে, তাই পণ্য উৎপাদনের গতি বাড়ানো সম্ভব। যন্ত্রগুলি দিনের শেষে ঘরে ফিরতে হয় না, তাই উৎপাদন ২৪ ঘণ্টা চলতে পারে। এটি খুবই গুরুত্বপূর্ণ, কারণ এটি ব্যবসায় কম সময়ে বেশি পরিমাণে পণ্য উৎপাদনের সুযোগ দেয়।

রোবটিক লেজার কাটিং-এর সঠিকতা এর শ্রেষ্ঠ দিকগুলির মধ্যে একটি। রোবটগুলি কম্পিউটার দ্বারা নিয়ন্ত্রিত হয়, যার অর্থ তারা প্রতি একবারেই সঠিক কাট করতে সক্ষম। অংশের মধ্যে সামঞ্জস্য অত্যন্ত গুরুত্বপূর্ণ হয় যখন অংশগুলি একইভাবে হওয়া আবশ্যক যাতে তারা সঠিকভাবে একসঙ্গে কাজ করতে পারে। যদি কোনো উপাদান খুব বড় বা খুব ছোট হয়, তাহলে এটি চূড়ান্ত উत্পাদনে সমস্যা তৈরি করতে পারে। রোবটিক লেজার কাটিং-এর প্রয়োগ নির্মাণের বিভিন্ন ক্ষেত্রে পাওয়া যায়। MINYUE অটোমেটিক ওয়েল্ডিং রোবট বিমান, গাড়ি, ভবন এবং যান্ত্রিক সরঞ্জামের জন্য উপাদান তৈরি করতে সহায়তা করে। উদাহরণস্বরূপ, তারা সূক্ষ্ম অপারেশনে সহায়তা করতে পারে এমন ছোট উপাদান উৎপাদন করতে পারে বা মহাকাশ অনুসন্ধানের জন্য গুরুত্বপূর্ণ হালকা উপাদান তৈরি করতে পারে। এবং এই তালিকা শুধু এই রোবটিক লেজার কাটিং প্রযুক্তির অসংখ্য সম্ভাবনার মধ্যে কয়েকটি মাত্র।

পাতা এবং ট্র্যাকিং ফাংশন ব্যবহার করে, ওয়েল্ডিং সিল স্ক্যান করে, ওয়েল্ডিং সিলের অবস্থান এবং তথ্য নিশ্চিত করে, 3D ডিজিটাল মডেল ড্রইং এবং আসল পার্টের মধ্যে ওয়েল্ডিং সিলের অবস্থান সংশোধন করে এবং ইনকামিং ম্যাটেরিয়ালের ত্রুটি এবং তাপ বিকৃতির কারণে বিপথগামী ওয়েল্ডের সমস্যা সমাধান করে।

বেইজিং মিনইউয়ে টেকনোলজি কো., লিমিটেড, যা বিশ্বের অগ্রণী উচ্চ-প্রযুক্তি প্রতিষ্ঠান যা শিল্পী রোবটের নন-টিচিং ইন্টেলিজেন্ট অ্যাপ্লিকেশনে বিশেষজ্ঞ। আমরা আমাদের সেলফ-ডেভেলপড রোবটস্মার্ট - ইন্টেলিজেন্ট ডিসিশন মেকিং সিস্টেম, স্মার্টভিশন - বাইনোকুলার স্ট্রাকচারড লাইট ভিশন সিস্টেম এবং স্মার্টআই - লেজার ভিশন সিম ট্র্যাকিং সিস্টেম ব্যবহার করে ফ্লেক্সিবল ইন্টেলিজেন্ট ম্যানুফ্যাকচারিং-এ বিশেষজ্ঞ। নতুন প্রজন্মের ইন্টেলিজেন্ট রোবট ওয়েল্ডিং এবং কাটিং সমাধান প্রদান করে।

শক্তিশালী ওয়েল্ডিং রোবট প্রদান করে সামনে থেকে লোড, পাশ থেকে লোড, উল্টোভাবে লোড, গ্যান্ট্রি মাউন্টিং, একাধিক রোবটের জন্য চালাক ট্রজেক্টরি পরিকল্পনা, একাধিক বহি: অক্ষ এবং অবস্থানীকরণ জন্য সহযোগিতামূলক কাজ। রোবট গতি সিমুলেশন, সংঘর্ষ ডিটেকশন, এককতা এড়ানো এবং অক্ষ সীমা ডিটেকশন সফলভাবে করতে পারে।

তাড়াতাড়ি, সঠিক, সম্পূর্ণ প্রোগ্রামিং-শূন্য, উচ্চ দক্ষতা এবং উচ্চ নির্ভুলতা। এটি ঐতিহ্যবাহী রোবটের জটিল শিখানো প্রক্রিয়া সমাধান করে এবং শিখানোর প্রক্রিয়ার জন্য ডাউনটাইম সংরক্ষণ করে।