Laser light sensors are devices that leds us see what is not easily visible to the naked eye. They use a laser — a powerful beam of light — to locate objects and determine how far away those objects are. Laser light sensors |We use laser light sensors in several day to day items such as automatic doors that open as one approaches them, robots, monitors, home security, etc. Lets get to know more about laser light sensors and how it makes our lives easier and better in this lesson.

MINYUE Laser light sensors are sensors powered by using a laser beam for detecting objects and measuring distances. Laser beam is a beam of light with a small cross-sectional area which can travel a large distance with very little spreading. When the Laser seam tracking system strikes an object, it reflects back toward the sensor. The sensor can calculate how far away the object is by measuring how long it takes the laser beam to come back. So we can recognize the things around us and where they are located.

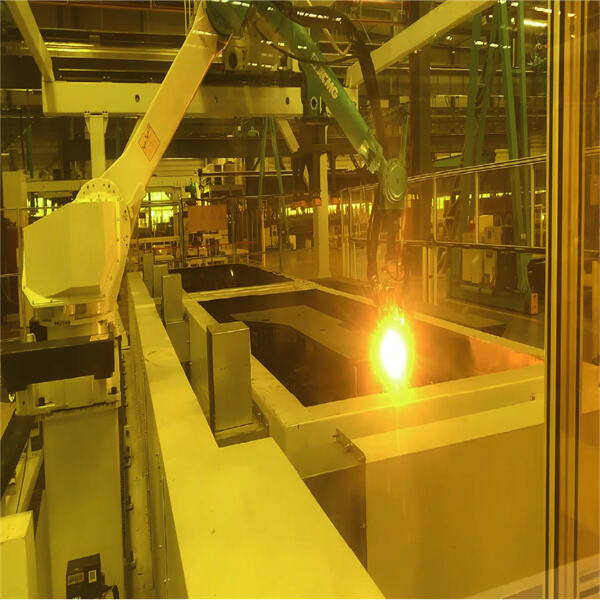

Many factories and industries use laser light sensors for a variety of purposes to make things easier and more efficient. And in the case of automatic doors, robot laser welding machine can sense if someone is near the door, which makes the door open without the need for physical touch or pushing a button. This is very convenient! In robots, these sensors guide the robots to walk with precaution and avoid colliding with the surrounding objects. For example, in security systems, laser light sensors can identify movement and inform us if there is an intruder in our premises. This protects us, and provides us with peace of mind.

There are many great advantages of using laser light sensors in machines and automation. One big benefit is accuracy. Laser light sensors can measure distances with very high precision, which is vital for manufacturing products on production lines and operating robots to perform repetitive tasks with accuracy. Another benefit is speed. The laser beam detector quickly locate things, enabling machines to operate more effectively and efficiently. This rapid pace is key to maintaining momentum in fast-paced workplaces. Additionally, MINYUE laser light sensors work extremely reliably and have widespread durability, so they are excellent for build-blocking machines that can not allow errors to exist in the work.

There are several important factors to consider when choosing a laser light sensor for your project. One key element is the distance the sensor can reach. Some will measure distances of a few meters (like a camera), others may see distances of several hundred meters. This is significant as in accordance with a venture of yours, you may require a wellspring of light that is equipped for seeing a significant distance, or simply to the short extent. Another point to keep in mind is the precision of the sensor. Different kinds of sensors give different levels of precision, depending on what you need for your application. Finally, take into account the sensor size and shape to ensure that it will integrate well with your other devices. You want to ensure that everything integrates seamlessly.

MINYUE Laser light sensors will only get better as technology continues to advance. Even so, more advanced laser light sensors even beyond that are coming that'll allow objects to be detected quicker and more accurately than usual. That way machines will run even slicker on tap. Laser light sensors could be used in unique and creative ways to benefit industries and businesses that we cannot even imagine yet. As technology continues to progress, imaginative applications for these sensors are likely to be developed, making them a vital element of our everyday existence.

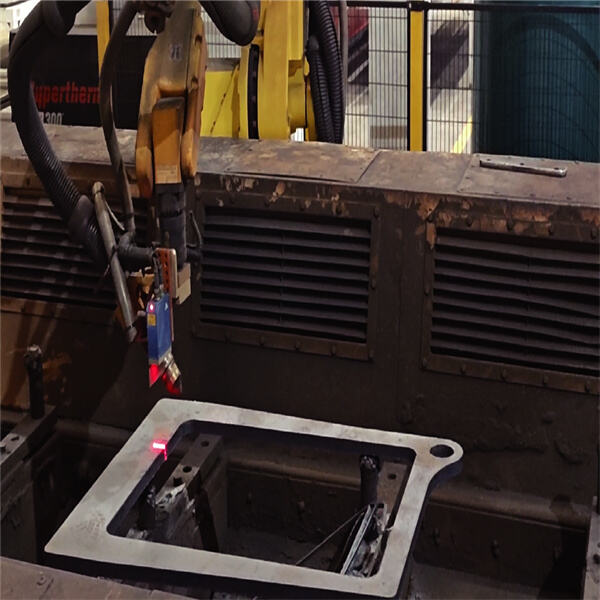

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.