Laser level sensors are designed very sensitive devices to a measure just in inches of height. They use robotic laser cutting, which are light beams, to calibrate everything to be just right. Trying to draw a straight line without a ruler is like really hard to do! However, a laser level sensor can ensure that you have accurate measurements every time you use it. The sensors make it considerably simpler to establish straight lines and level surfaces.

Building things is basically like assembling one large puzzle that has to fit just right. So, each piece of the puzzle represents a part of the building. Laser level sensors assist builders in ensuring that everything is positioned properly. They can also see whether a wall is straight or a floor is level. Well, these laser beam sensor are crucial tools in order to get the job done right. Laser-guided sensors allow construction employees to perform their work more quickly and with greater assurance that their measurements are correct. That way, they can avoid making mistakes that could create problems down the line.

Time is very precious in big factories and warehouses because it helps save money. Laser level sensors make measurements by a worker faster and more accurate. Meaning, they can do their work in less time. So, when you're working on building a giant machine, one of the things, you're very careful, all the parts fit together very closely. If they don’t, the robot laser welding machine could malfunction. Laser level sensors ensure that everything is in place, saving time and money in the long run. These sensors also free workers to concentrate on more consequential activities, confident in the knowledge that all measurements are accurate.

It can be hard to measure distances, particularly if they are very far away or difficult to access. Sometimes we need to measure stuff up high or down low and that makes it difficult. This is where laser level sensors come in very handy. They shoot lasers to measure distance in charge time quickly and accurately, including in hard-to-get-to places. This is particularly beneficial on construction sites, where getting it right is vitally important. Laser level sensors are homework-savers for workers who can reduce the risk of mistakes and save time, allowing for better results. It enables more effective and safe project fulfilment.

Robots are advanced machines that can perform a wide variety of tasks. They can assist us with tasks that may be dangerous or difficult for us. Laser level sensors are used to provide vision and measurement to robots, improving their working efficiency. For instance, a robot that works inside a warehouse can use laser level sensors to navigate around obstacles and properly pick up items without hitting anything. All this would not be possible without the use of sensors; allowing robots to perform quicker and more accurately, making them very useful equipment in many jobs.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

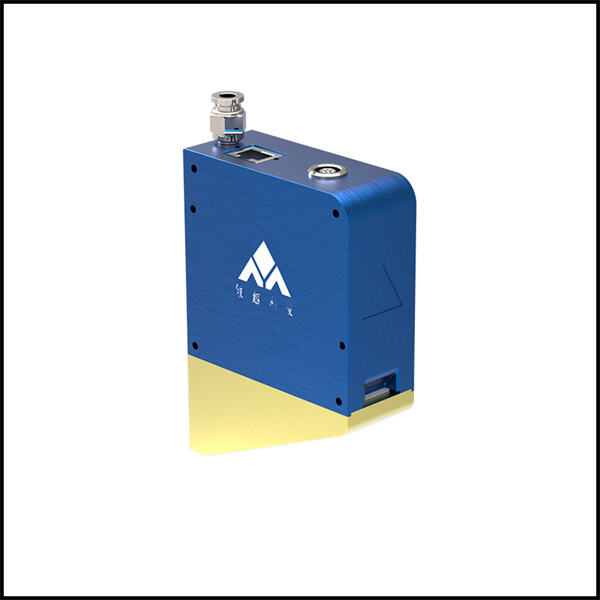

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.