Railway construction is a huge profession which helps people in moving from one place to other place. When you think of trains, you might forget about the thankless labor that goes into ensuring the rails are safe and sound. Welding is one of the important jobs in rail construction. Here, workers connect the rails to create a solid path for the trains. Running trains on tracks is a necessity. But this process of welding used to be very slow and labor-intensive. However, those have become much convenient and rapid because of the ground rail welding workstation from MINYUE.

Benefits of Using Ground Rail Welding Workstation One of the biggest advantages is that it allows workers to complete their tasks significantly faster. It also means trains can operate on the lines faster, which is positive for anyone who wants to travel. Additionally, the use of this MINYUE Ground rail welding station allows to correctly weld the rails together. Whenever it is required to put the rails together properly, there are chances of accidents occurring. That is super important, because trains are a popular way for people to get around — and we want to make sure we are keeping everyone safe. The safety of rail travel is everyone’s business.

With a short duration experience at Works Full Circle, this article is loosely based on my first project as I have been working here.

Previously, when there was no stationary rail welding work bench, most of the time needed to prepare equipment for workers. They needed to get all of their tools, make sure everything was perfect, then they could start welding. It may take a while and could be boring. However, the process is now significantly improved and less time-consuming with the MINYUE ground rail robot cell. Workers can spend more time on what they’re best at — welding the rails — and not set up their tools. This shift allows them to complete their jobs more quickly, as well as execute higher quality work. When workers have fewer distractions and can focus on welding better, they yield better results.

Always very important in railway work is the safety. Keeping workers safe by using a ground rail welding workstation helps, as it allows you to ensure that the rails are welded together correctly. And when everything works as it should the accidents become fewer, and that's a win/win for all people who use trains to travel. If safety is important to you, MINYUE's ground rail welding workstation should be your first choice. It allows workers to perform tasks and ensure they’re working according to safety protocols. This leads to a more secure feeling for the workers as they go about their jobs.

Here are some tips that can help workers get the most from their ground rail welding workstation. Before beginning work, workers must ensure they have all the required tools and equipment. MINYUE robotic welding cell can really help how seamlessly the job runs, having everything set up and in place. Second, employees should ensure that they take time off when necessary. As noted, taking breaks in between job helps them re-energize and continue their welding business. Lastly, following safety rules and instructions by workers is essential. This is to make sure they are safe with versus each other when they are working the tracks.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

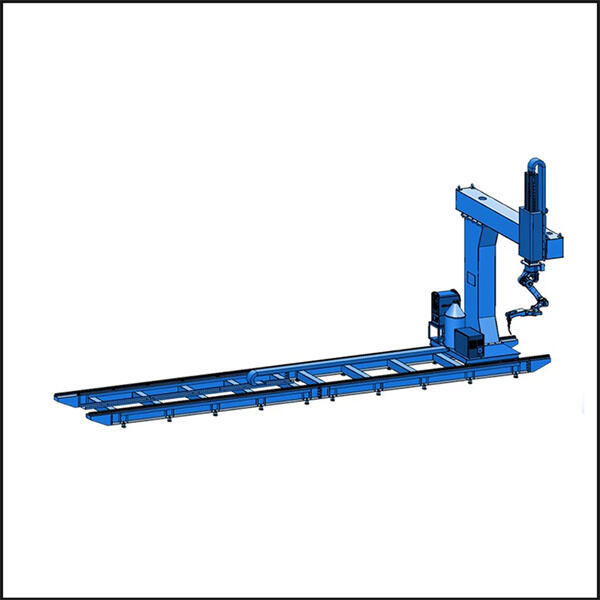

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.